The Forward Thinker

Britton Timbers has been producing beautiful timber products in Tasmania’s north–west for more than 110 years. They’re experts in processing native timbers, and as such they have a reputation throughout Australia, and indeed internationally, for high quality products that can be trusted to be technically sound and visually appealing. But building longevity and a strong reputation doesn’t happen by accident. It takes some forward thinking.

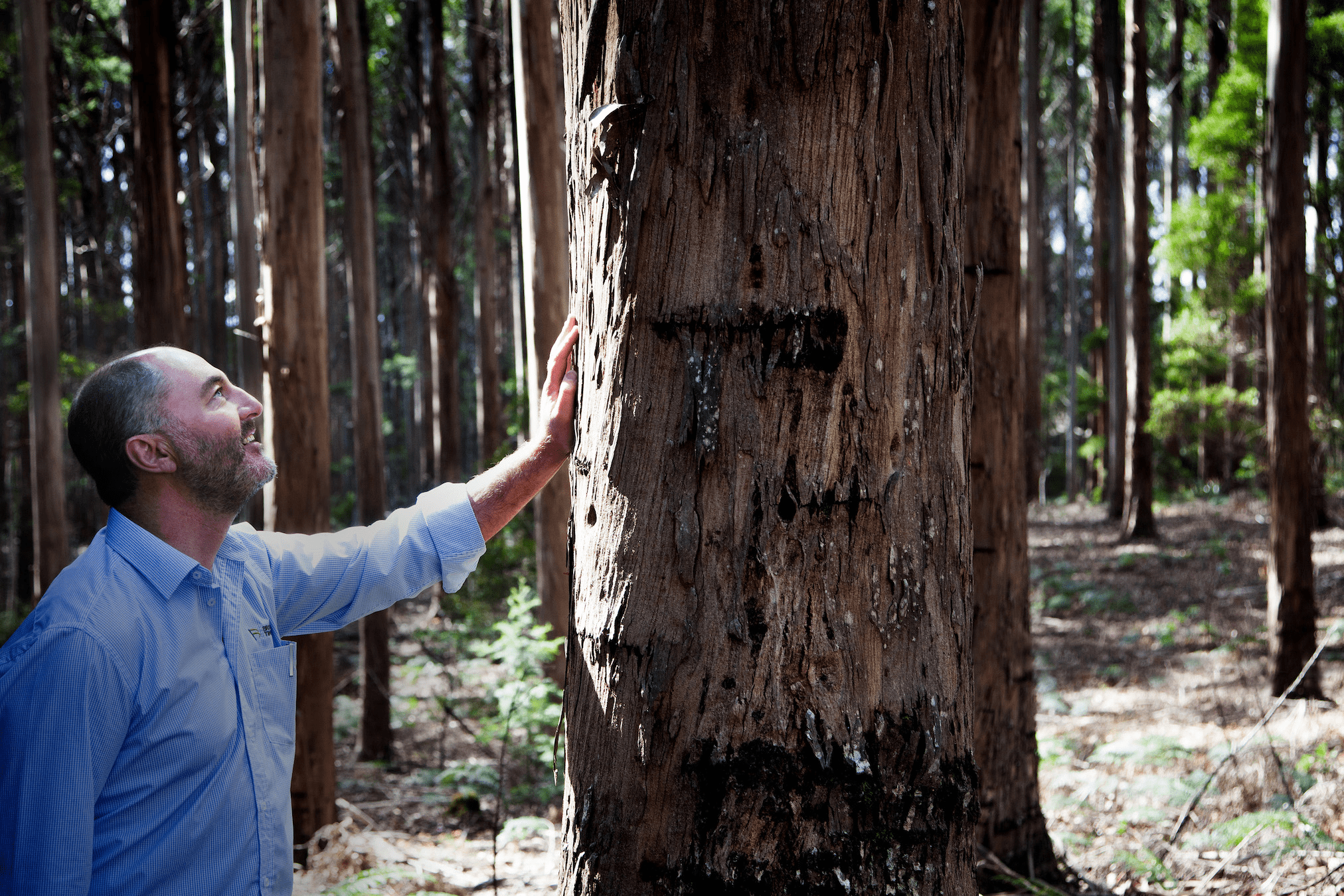

Shawn Britton, Director of Britton Timbers, is looking to the future by investing in research and technology to deliver sustainability for his business, his community, the resource and the planet.

Investing in a resource for the future

As the credentials of timber as the Ultimate Renewable resource becomes more widely understood, the demand for timber is on the rise. And with a trade deficit of over $2 billion in our country, we need to produce more timber at home.

In Tasmania, increased supply won’t be coming from our native forests. The sustainable yield in our native forest resource is set, allowing for the production of high–quality forest products, and maintenance of one of the most extensive wilderness reserve areas per capita on the planet. So, we must look to tree crops as a supplement to our regenerated native forest resource. But a plantation grown hardwood log does not behave the same way as a native forest log.

“Plantation grown logs are eucalypts, but they are a different species and they have a lot more natural stresses than native forest timbers because they are fast grown,” explains Shawn.

“This means that the timber fibres tend to split using conventional drying methods which causes holes or cavities to open up within the timber. For structural soundness and appearance products this is an unacceptable defect that makes the timber unviable for virtually any product.

“That is why we are investing heavily in research in collaboration with Sustainable Timber Tasmania and the University of Tasmania’s Centre for Sustainable Architecture with Wood (CSAW) to find new methods for drying plantation grown hardwood.”

Plantation grown logs are also smaller in diameter than native logs, which will require an investment in new processing technology.

“We can see the value in the investment because we believe we can find a way to utilise plantation grown hardwood to create timber suitable for high value markets like fine furniture, joinery and veneers,” says Shawn.

Britton Timbers is also investing in research to improve the characteristics of plantation timbers to be more suited to a wide range of uses like flooring and external cladding, which could replace imports from overseas.

“Plantation grown timber is currently not durable enough or flooring or external use. But we’re exploring densification processes to make the timber harder. This would allow it to be utilised for these applications,” says Shawn.

Investing for sustainability and a better carbon balance

Investing in in a resource for the future will not only create sustainability for Britton Timbers, it will create confidence for others to invest in managed plantations.

“Farmers and private forest growers need confidence in the future marketability of plantation grown timber if they are going to be enticed to plant and manage trees as an investment. It is a crop that needs to be managed for 25–30 years before it will provide a return from solid timber,” says Shawn.

Growers can harvest their tree crops earlier, at around 15 years, and sell the wood as fibre for paper, but the end product (paper) does not store carbon for as long as a solid timber product.

“Investing in plantations is not without risk, and it requires upfront and ongoing investment to maintain. But if we are successful in finding processing solutions from this research there will be opportunities for growth into new high value products for processors and markets for growers.

“We understand that wood is the Ultimate Renewable and getting more trees in the ground is part of the solution to climate change. Having a market for the end product is the key to that,” says Shawn.

“These high value markets will prove to growers that its worth keeping their trees in the ground for longer knowing they will get a higher return.”

Processing plantations will allow Britton Timbers to increase supply of sustainably managed, certified timber into the marketplace, but it will require a significant investment in a modern speciality processing plant.