There has never been a better time to plant trees

There is a global shortage of timber, and farmers are the key to delivering the commercially viable resource of the future. In fact, the global demand for timber is expected to quadruple by 2050 (The World Bank, 2016). Within Australia demand is being driven by the home building market and the desire to replace carbon intensive materials and plastics with natural, recyclable and renewable products. In Tasmania, research into plantation grown hardwood is now coming to fruition with new high–value products close to hitting the marketplace. Technology is also unlocking new uses for materials derived from trees, like ‘green’ chemicals and biofuel. Providing enough timber and fibre to meet this increased demand presents both a challenge and an opportunity. Farmers are in the box seat to capitalise on this opportunity – there has never been a better time to plant trees.

The Building Market

It is estimated that 2 billion square metres of new building stock will be needed every year between 2020 and 2025, especially for housing. The outcome of numerous studies show that 400,000 hectares of new plantations are required over the next decade to meet the demand for timber and wood fibre in Australia alone. This amounts to a billion new trees in the ground. This target is in addition to the 70 million trees planted every year in Australian plantations to replace those that have been harvested.

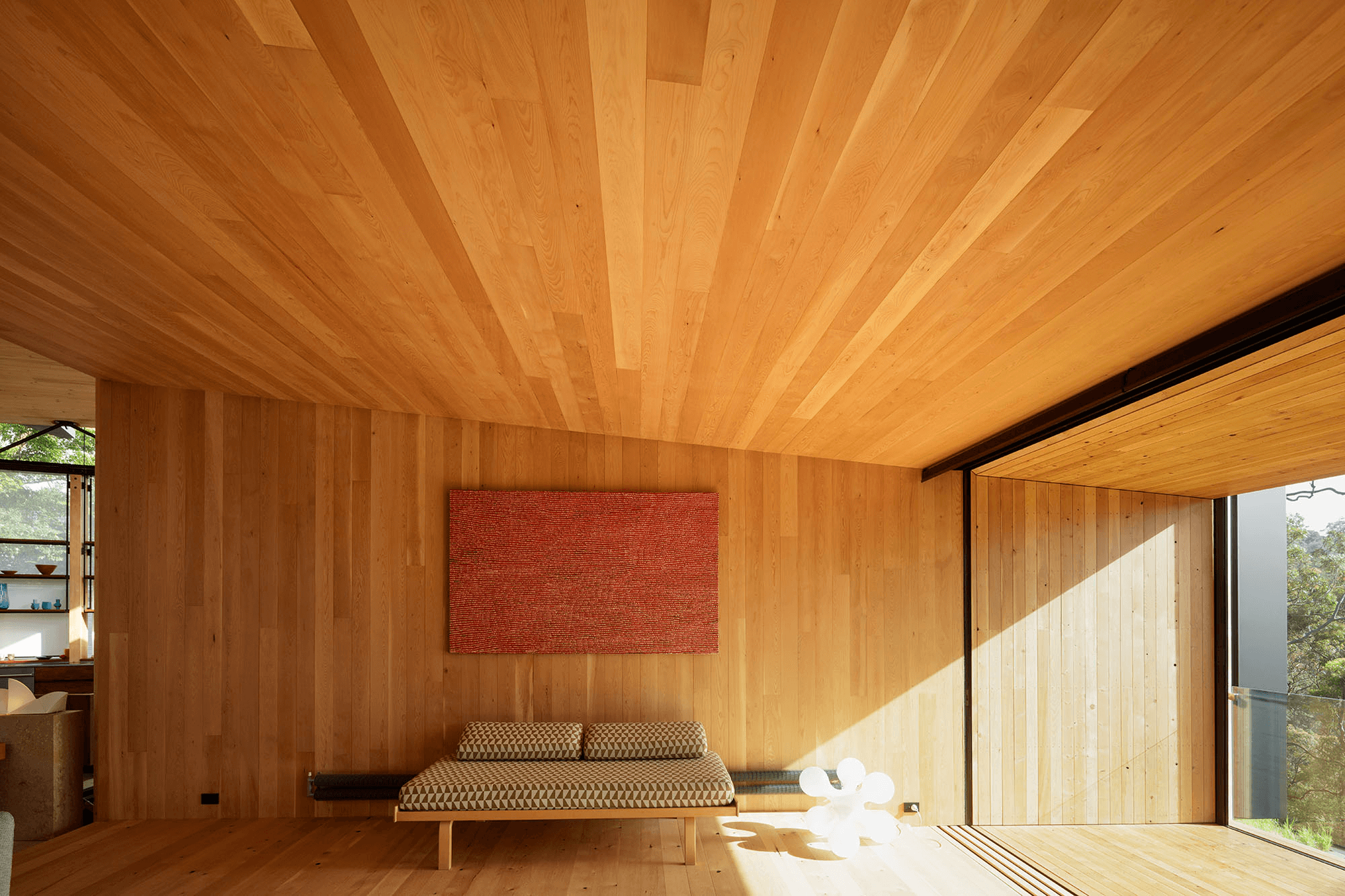

As well as the home building market, the high demand for sustainable timber in Australia is fueled by the desire to replace carbon intensive materials and plastics with natural, recyclable and renewable products. The construction industry alone produces around 15% of Global Carbon Dioxide Emissions. Timber is a natural, traditional, beautiful and renewable construction material. It is less carbon intensive to manufacture, transport and erect than structures made of other common materials. It’s no wonder we are now seeing construction of high–rise buildings made completely out of wood.

In recognition of these benefits, Tasmania was the first state to launch a Wood Encouragement Policy, which ensures sustainably sourced wood is fully considered, where feasible, in Tasmanian government procurement, particularly for new buildings and refurbishment projects.

New Products Derived from Plantation Grown Hardwood

In Tasmania, research into plantation grown hardwood is set to result in a range of new high–value, renewable products to hit the marketplace in coming years. In their quest to add value and waste nothing, Tasmanian timber processors and researchers in collaboration with the National Institute for Forest Products Innovation have been working to produce high–value plantation grown hardwood products for nearly two decades. Engineered wood products in particular are now coming to fruition.

Tasmania has two types of plantation hardwood – thinned and pruned for solid and appearance grade wood products and fibre–managed material, which is primarily grown for pulp. All of Tasmania’s major timber processors are now working with thinned and pruned material through several trials to develop products for commercial application.

The research trials include:

- Using sensing technology and digital tools to predict moisture content during air–drying with a view to improving timber value;

- Testing the feasibility of commercial scale treatment and modification of Eucalyptus. nitens and Eucalyptus. globulus sawn boards, and eucalypt wood panel samples, to improve durability and fire resistance;

- Developing a new generation of Tasmanian appearance hardwood products for in–state design and manufacturing – including flooring and linings that can be applied in domestic and commercial buildings;

- Using sensor technology to examine how plantation grown material may vary through the supply chain; and

- Developing laminated structural elements from fibre–managed plantation hardwood.

Michael Lee, Technical Officer at the Centre for Sustainable Architecture with Wood at the University of Tasmania says, “we have had some very encouraging results and we’re about 80% of the way to commercial production.”

Fibre–managed plantations are now also being used for structural purposes through Cross Laminated Timber (CLT), Glue Laminated Timber (glulam) and plywood products for the Australian and international market. Glulam is an engineered wood product made from structural adhesives that are bonded with the timber to create a moisture resistant and highly durable timber product.

“You can make anything you like of any structural size with Glulam products. It’s making a larger piece of timber out of smaller pieces of timber through finger joining and gluing pieces together,” says Lee.

Using state–of–the–art technologies Lee explains that if you can dream it, you can do it when it comes to glulam products.

“We have the ability to make any shape or any form that you would like through computer numerical controlled (CNC) routing with 5–axis routers and other bits and pieces.”

Extracting Greater Value from all Parts of the Tree

The unprecedented demand for sustainable products is driving research and innovation across the world. Research and new technology have uncovered new and exciting ways to use materials derived from native and planation trees such ‘green’ chemicals, biofuels to replace fossil fuels, food additives, pharmaceutical and medical applications, and wood plastics that can be turned into anything from car components to recyclable replacement plastic bags. These new technologies are helping to extract greater value from all parts of the tree.

Biofuels

Utilising tree residues for bioenergy can substitute fossil fuels such as coal, NPG and LNG. Biofuel is the way of the future and Tasmania is well placed to become an industry leader in this field. A state–of–the–art pellet mill has been commissioned at Mowbray, near Launceston, to turn all timber waste from the production process into value added bio energy pellets for the Australian heating market. Wood waste previously destined for land fill is now a precious resource. The Tasmanian heating market, which has relied on importing pellets from New Zealand and Victoria, can now source competitively priced pure hardwood heating pellets locally. A feasibility study is currently underway for a much larger pellet mill in Tasmania’s south.

Biochemicals

Local businesses are now producing bio–chemicals such as the new industrial solvent called Cyrene, from wood. The global market for polar aprotic solvents such as Cyrene is presently around 900,000 tonnes. In fact, four of the six major polar aprotic solvents used in pharma– and agri–chemical industries that Cyrene can displace are being phased out by health and environmental regulations.

Plantation Growth will Rely on and Reward Farmers

The next generation of plantation growth in Australia will rely on and reward our farmers. The sustainable revolution is only just beginning. It’s not a fad. Technological advances will come thick and fast, with an array of exciting new ways to use the natural materials derived from trees.

Investments in planting trees today will pay dividends for future generations as these trees mature and become available for wood and fibre supply. Just as forward–thinking scientists and entrepreneurs harnessed coal to create opportunity towards the end of the previous millennium, it will be those that come up with sustainable alternatives that are most successful in this one. The resource of choice in our time is renewable.

According to the Australian Department of Agriculture, forest industries’ working with farmers to secure a long–term ‘wood bank’ for the future will be an economic win for all the parties involved. There has never been a better time to plant trees.

Links:

https://nifpi.org.au/projects/

https://www.agriculture.gov.au/forestry/publications/growing–better-australia